Servicing The Greater Philadelphia Area

CALL: 484-442-0855 | EMAIL: info@envelopegroupco.com

That’s because spray foam insulation expands up to 100 times its volume to fill gaps where heat and air conditioning can escape. Cellulose and fiberglass can be loosely packed, which can result in drafty spots or stuffy areas in a building.

Spray foam insulation helps you give them exactly what they want. In fact, Spray Foam Insulation can help reduce heating and cooling costs by up to 50%. Savings may exceed insulation costs in just three to four years on average. The investment then continues to pay off in the form of monthly savings for the life of the home.

Because less energy is needed to heat and cool a home with Spray Foam Insulation, HVAC capacity needs may also be reduced, saving you and your clients more money and possibly freeing up space within the design. HVAC design software can help you estimate the reduced heating and cooling loads.

Protecting against air leakage with spray foam means that homeowners can significantly reduce CO2 emissions and save up to 50% in energy costs related to heating and cooling. On average, the energy savings can exceed the installation price within three to four years. Plus, an energy saving air seal helps keep airborne pollutants, allergens and moisture out ensuring a healthier and cleaner indoor air environment.

Spray foam’s dual performance function of R-Value plus air sealing also means that the amount of building materials required is less and can also shorten construction schedules. Spray foam works for the life of the building, eliminating the need for replacement or additional materials and waste.

When measuring the effectiveness of insulation, R value is the only factor most insulation manufacturers talk about because it’s all they offer. R value measures the ability to limit conductive heat flow (heat transferred through it). But the primary method of heat transfer is not conductive heat flow — it’s air leakage (convection). Air leakage can account for up to 40% of a building’s energy loss, and it cannot be stopped with traditional insulation. R value is important, but an airtight seal is equally important for achieving energy savings.

Flexibility for Applications – Builders can effectively seal any intricate or unique design without project delays.

Suitable for All Projects – Envelope Group offers an array of specialized formulas and can provide the correct insulation for any housing or renovation project regardless of climate zone.

Benefits:

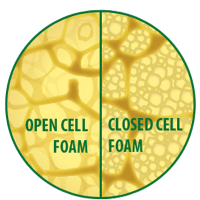

Key Advantages of Open Cell

Benefits:

Key Advantages of Closed Cell

If the spray foam insulation is used in any part of your home used as a living space, it should have a thermal barrier that has been tested and approved for use with the spray foam. Thermal barriers are designed to protect against direct fire damage to spray foam adjacent to living areas for at least 15 minutes. A thermal barrier might be a material such sheet rock, plywood or particleboard, or a painted-on fire proof coating.

If the spray foam insulation is used in any unoccupied part of your home, such as an unoccupied attic or crawl space, it should have an ignition barrier that has been tested and approved for use with the spray foam. An ignition barrier is a fire protective coating designed to inhibit or prevent the start and spread of fire from a spark or direct heat on the spray foam surface. Ignition barriers are usually spray-on or brush-on coatings.

If you’re using an open-cell spray foam insulation in a cold climate, you’re usually required to have a vapor barrier or vapor diffusion retarder on the interior (warm in the winter) side of the insulation. This blocks moisture movement from inside your house to the outside, where it may condense and freeze. Vapor barriers / vapor diffusion retarders are typically membranes (plastic sheets) or brush-on coatings.

Closed-cell spray foam insulation typically doesn’t require a vapor barrier or vapor diffusion retarder.

If you’re using an open-cell spray foam insulation in a hot and humid climate you?re usually required to have a vapor barrier or vapor diffusion retarder on the exterior side of the insulation. This blocks moisture movement from outside your house to the inside, where it can cause mold and increase the amount of energy you need to cool your home. Vapor barriers / vapor diffusion retarders are typically membranes (plastic sheets) or brush-on coatings.

Closed-cell spray foam insulation typically doesn’t require a vapor barrier or vapor diffusion retarder.

Vapor barriers or vapor diffusion retarders aren’t generally required in hot and dry climates.

Servicing Southeast PA, Delaware & NJ Since 2011

PA HIC #: PA080729 | NJ HIC #: 13VH07062300

The Envelope Group is your local expert on creating a comfortable and energy-efficient building envelope for all of your commercial and residential needs. The Envelope Group helps homeowners, builders, and architects to appreciate the multiple benefits of a better building envelope in homes and businesses.

© Copyright Envelope Group Co, LLC. All right reserved. | WEBSITE CREDIT